Products

QDP Ceramic Films

Ice Cool Grey Films

High Performance Films

NR Quick Dry Films

NR Quick Dry Plus Films

Benefits of Safety Glazing

Temperature Regulation

Safety films come with heat-rejecting properties, helping to regulate interior temperatures by reducing heat gain from sun.

Energy Saving

Safety Glazing for vehicles reduces the load on air conditioning systems, resulting in fuel savings.

Cost-Effective Solution

Compared to replacing entire glass panels or windows, installing Safety Glazing is a more economical way to enhance safety and security. It provides a durable and long-lasting solution at a fraction of the cost.

Enhanced Security

The film adds an extra layer of security to windows, making it more difficult for potential intruders to break through.

UV Radiation Blocking

Safety Glazing offer UV protection, helping to block harmful ultraviolet rays.

Shatter Resistance

Safety Glazing is designed to hold glass fragments together upon impact, minimizing the risk of shattered glass.

Why Safety Glazing?

Minimum Light Reflection Provides better visibility.

Cost effective solutions with better cooling effect.

Soothing Colors to enhance aesthetics of Vehicle glasses.

Reduce Glare up to 96%.

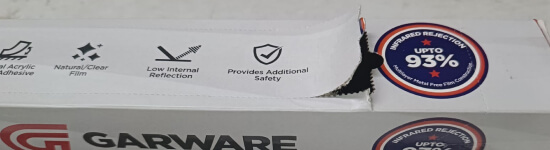

Seal of Quality - Global Safety Glazing Film

Non Re-usable Packaging Material

The perforated box with an enclosed tube design guarantees that the item is in unused condition.

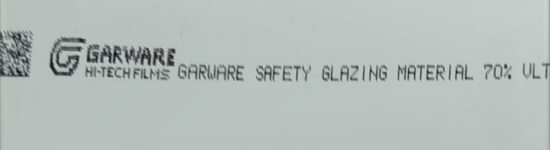

Genuineness of Films

You will see the Dot code and SKU name printed on the film for the purpose of verifying the genuineness of Global.

Transparency Check

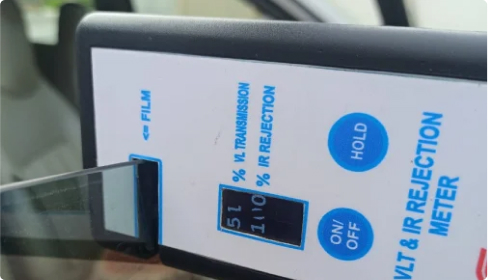

VLT & IR Rejection Meter

The VLT meter is a device that measures the amount of light that can pass through the windows of a vehicle. As per the rule there should be 70% VLT in the front and rear , 50% for side windows. Can be used to prove the overall transparency level of the glass if needed.

Customer Testimonials

Customer #1

Customer #2

Customer #3

FAQ's

No, PPF will not always peel up on edges. While it is a tough and self-healing protective layer, the quality of installation plays a crucial role. Proper prep work and training of the installation technician significantly impact the installation’s quality and ensure a perfect finish. At Global, we provide training to ensure professional installations that minimize the risk of peeling edges.

Customers should consider purchasing PPF for their vehicles due to its key features:

A. Excellent optical clarity: PPF provides a transparent and high-gloss finish, preserving the original appearance of the vehicle.

B. Excellent stain resistance: PPF resists stains from common contaminants like bird droppings, bug splatters, and tree sap.

C. Self-healing property: The specialized topcoat of PPF has a self-healing ability that helps to reduce the appearance of minor scratches.

D. Hydrophobic property: PPF repels water and prevents water spots, making it easier to clean and maintain the vehicle.

E. Non-yellowing property: PPF is designed to resist yellowing over time, maintaining its clarity and color.

F. Easy installation on curved surfaces: PPF is flexible and can conform to the contours of curved surfaces, ensuring a seamless and precise fit.

We recommend using PPF within 1 year from the date of manufacturing. Using it within this timeframe ensures optimal performance and adhesion.